Energy Glass Solar™

Patents & Solar Architectural Glass Specifications

Technology Overview

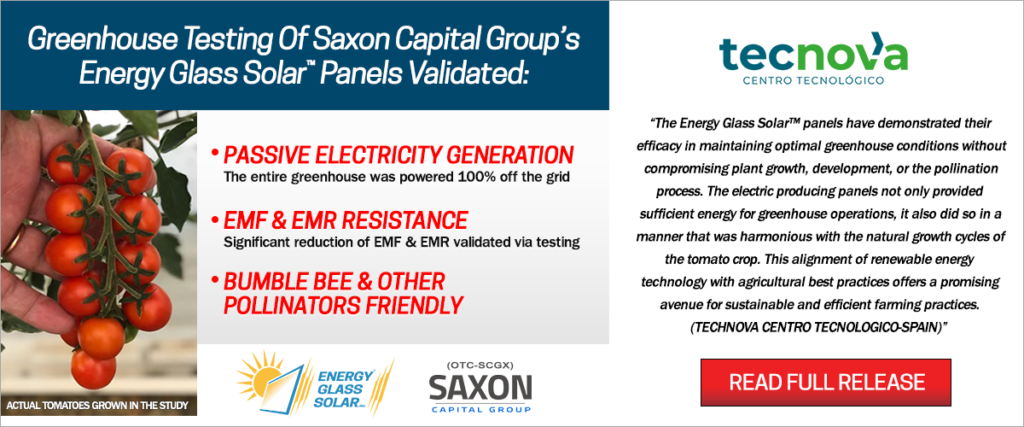

Energy Glass Solar™ is a glass clad polycarbonate consisting of one or more plies of proprietary Nano interlayer, two or more plies of patented bonding film, glass and/or glass ceramic. Thickness of product ranges from ¼’’ through 3-1/2’’. Energy Glass Solar™ is an electrical producing glass, which in addition to its electrical producing qualities may be fabricated as a defense against bullet, bomb blast, forced entry, fire, hurricane, typhoon, tornado, earthquake or any other threat of a man-made or natural origin.

The Science Behind Energy Glass Solar™

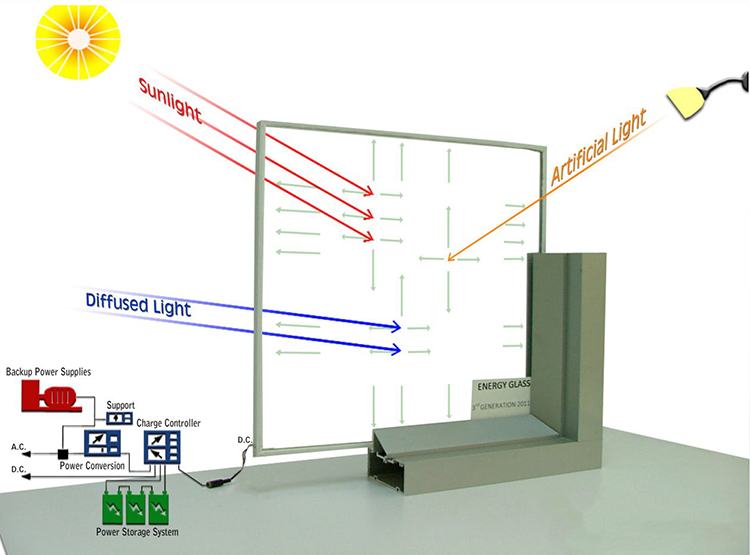

Our Trade Secret technology is generated in our laboratory which fabricates and refines a specific nano particle that is then co-extruded into the Energy Glass Solar™ single source interlayer giving it the unique ability to explode and direct light while remaining visually clear.

The light is directed to the periphery of the glass and/or polymer product, at which time the light is converted into electricity.

The patented, competitively priced electrical producing glass collects and converts sunlight, diffused, ambient, artificial and ground reflectance light into electricity.

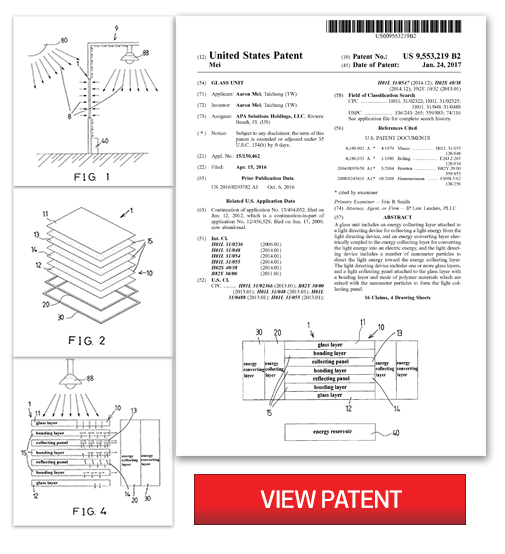

The Company owns and, or controls over 100 patents and over two hundred formulae for nano technology and products, such as but not limited to: nano carbon capsule that is specifically modified to enhance and reflect light energy, that the Company uses in its Energy Glass Solar™ electrical producing glass.

- Trade Secret Technology

The company owns nano reactors and proprietary process which fabricates nano particles that are utilized to explode and direct incident light which is then converted into electricity.

-

US Patent

Co-infusion of nano particles into bonding films, smart films, coatings, cement products, medical products (drug delivery biocapsule implants), nano wires, membranes, semi conductor electronics, fluids, oils and graphene.

Architectural Glass Specifications

The intent of this specification is to clearly define the correct electrical producing glass product and protocol. A format and general data are named in this text to aid in the future specification of a chosen product and make up.

- Product Description: Energy Glass Solar™

- Product Usage: Natural And Man-Made Disaster Resistant Glass That Is Also Passive Electrical Producing.

- Thermal Values: Up To And Including BREEAM & LEED Platinum.

- One Sample of Many Specifications For Energy Glass is GSA Level D Bomb Blast Resistant and Miami Dade Hurricane Resistant:

- Float Glass thickness: [6mm ].

- Glass color: [multiple].

- Coatings: heat resistant.

- Float Glass thickness: [6mm]

- Bonding Film: [Saf-Glas Patented]

- Bonding Film Thickness: [multiple]

- Bonding Film Color: [Clear]

- Interlayer Thickness: [multiple]

- Interlayer Color: [multiple]

- Make ups include insulated, double insulated and

triple insulated glass

- References:

[ASTM International] American Society for Testing and Materials Applicable ASTM Standards: [C 1036], [C 1048], [C 1172], [C 1349], [C 1376], [C 1464], [E 1300]

[GANA] Glazing Association of North America; [Full manual inclusive of table IV &01-0300].

[ANSI] American National Standards Institute; [ANSI Z97.1 – 2004].

[ASCE] American Society of Civil Engineering; [ASCE 7-98].

[CPSC] Consumer Product Safety Standard; [16 CFR 1201].

[UL] Underwriters Laboratories; [UL-9 & UL BR Levels 1-8].

[NIJ] National Institute of Justice; [BR Levels 1-4].

[NFPA] National Fire Protection Association; [NFPA 257]. - Quality Assurance Standards:

1. Miami Dade County Quality Assurance Manual.

2. Underwriters Laboratories Follow Up Service; Files R20487 & R22338

3. Qualification Standard:

1). Dade Hurricane certification 22.0809.04

2). GSA Level “D” Bomb Blast

3). UL 972

Now Accepting Projects